Charcoal furnaces

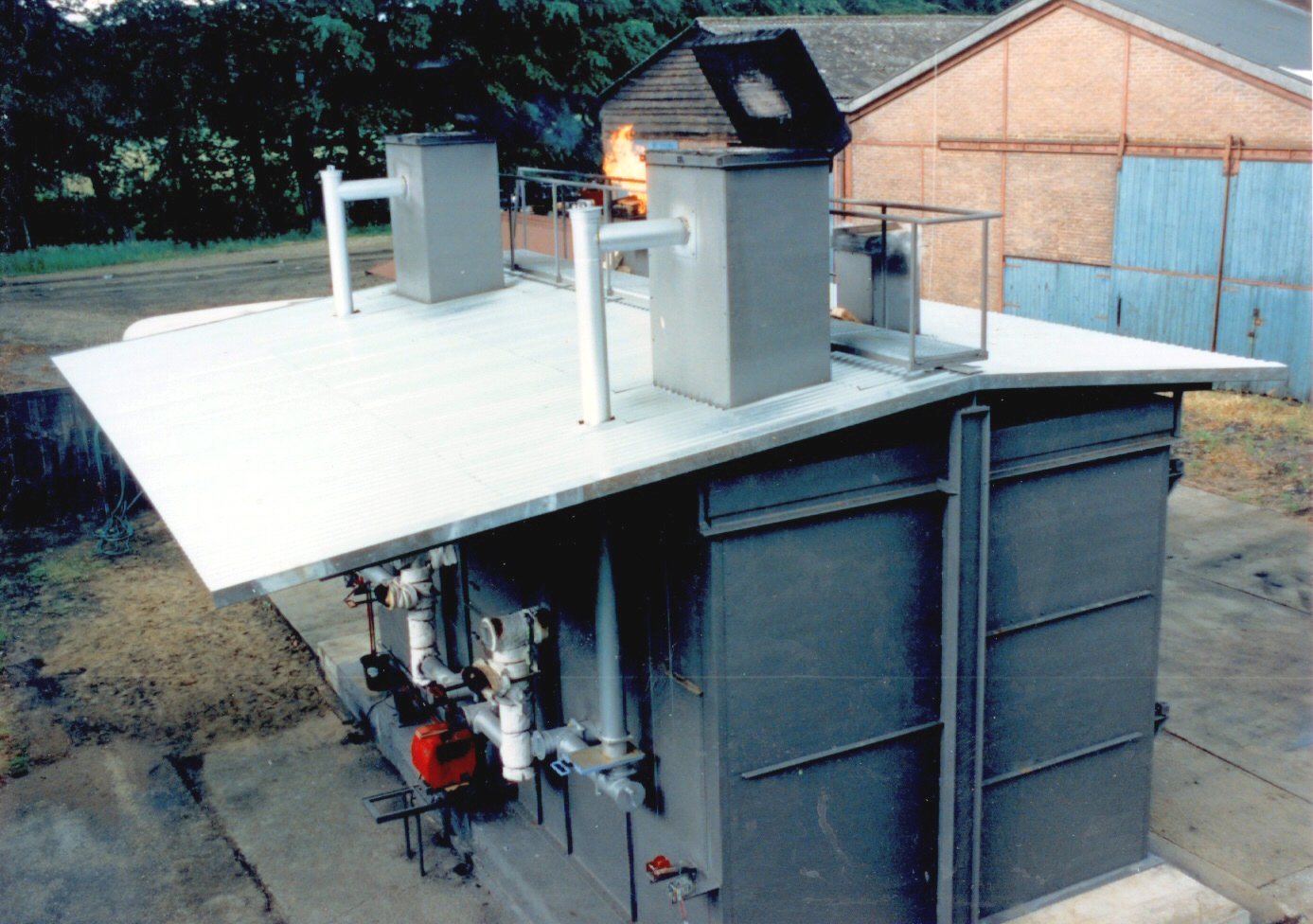

MOVI charcoal furnaces (C.M. Technology b.v.) is a full member of the MOVI vuurvast group. This company develops furnaces for the carbonisation industry. We have been working for over 25 years to improve technology of efficient and CO2 neutral production of charcoal. The quality has to be constant high with NO pollution for the environmental. In the “projects” below, you can also see our older “VRM system” and the “HEAD system”. These systems produces good charcoal, but are expensive and difficult to move to another production location. That is why we have developed a new type of furnace for making high quality charcoal. This furnace is MOBILE and can be PLACED EVERYWHERE and no extra building is needed. The complete installation needs only a flat and solid surface and a small roof. With this furnace you can produce the same amount of charcoal as the “HEAD system” and the “VMR system”, but with a much smaller investment.

The capacity (about 700-1000 tons/year) is depending on the production time, the % carbon fixed, the wood quality and the moisture of the raw material. For 800 tonnes of charcoal you need ± 3200 tonnes of air dry raw material (with a moisture content of 15-20%) or waste wood from a sawmill or furniture factory’s. With this furnace it is possible to make charcoal with a very high percentage of carbon fixed. Also you can reach a very constant quality, which is important for the industry and the restaurants. The furnace is a continue process, and the best is a production of 24 hours, 7 days a week. You can stop the process, but it will take extra time (and fuel) to get the installation running again. You need only fuel (diesel/gas) for heating up the installation, when the installation is on temperature you need no (or very less) extra fuel anymore. The installation burns on the wood gases of the product.