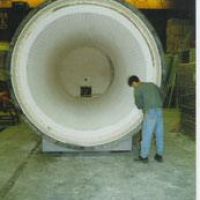

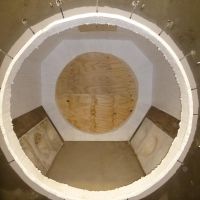

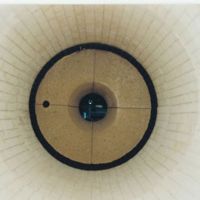

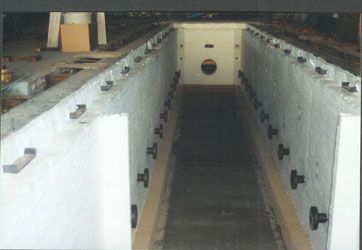

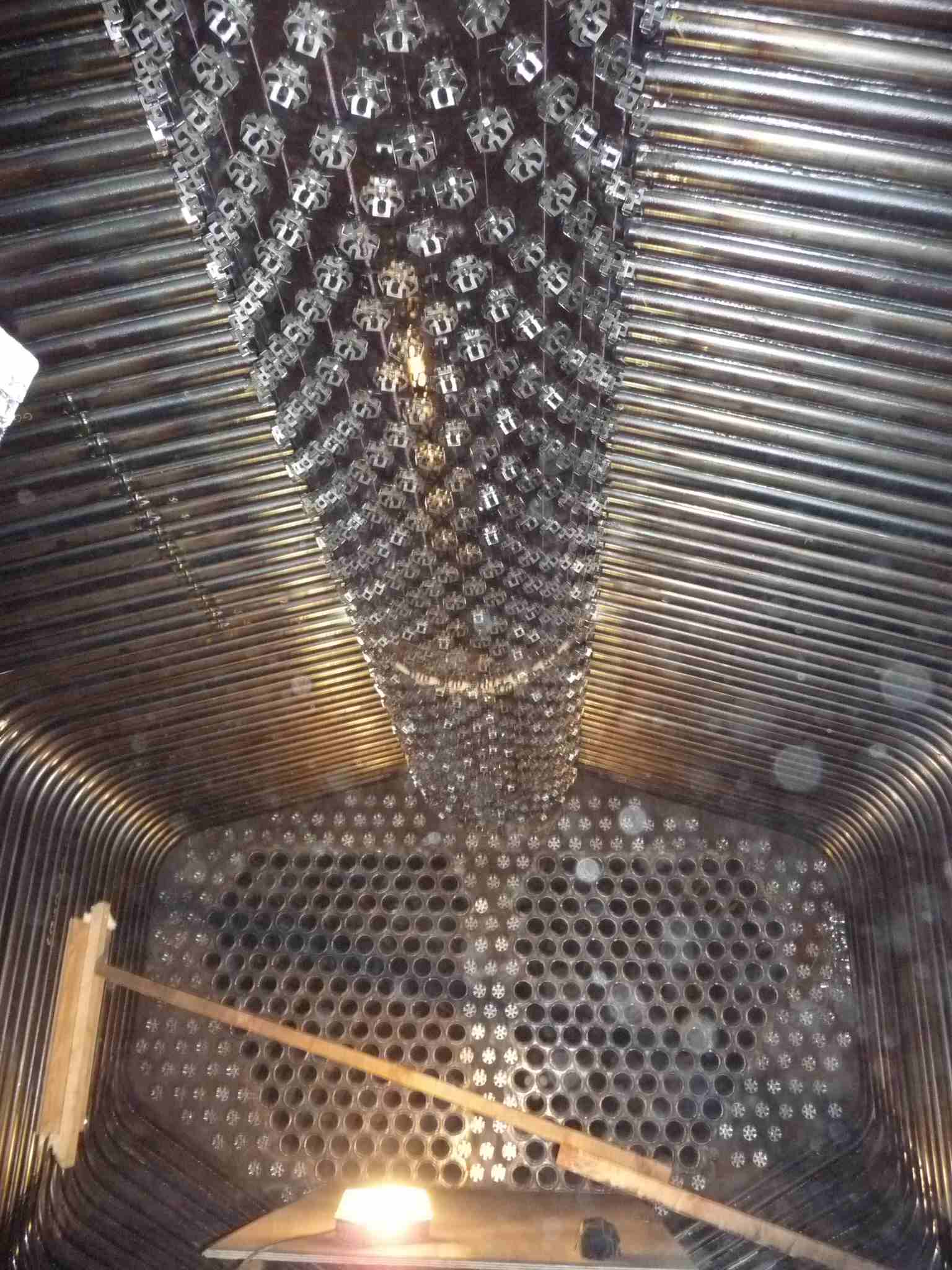

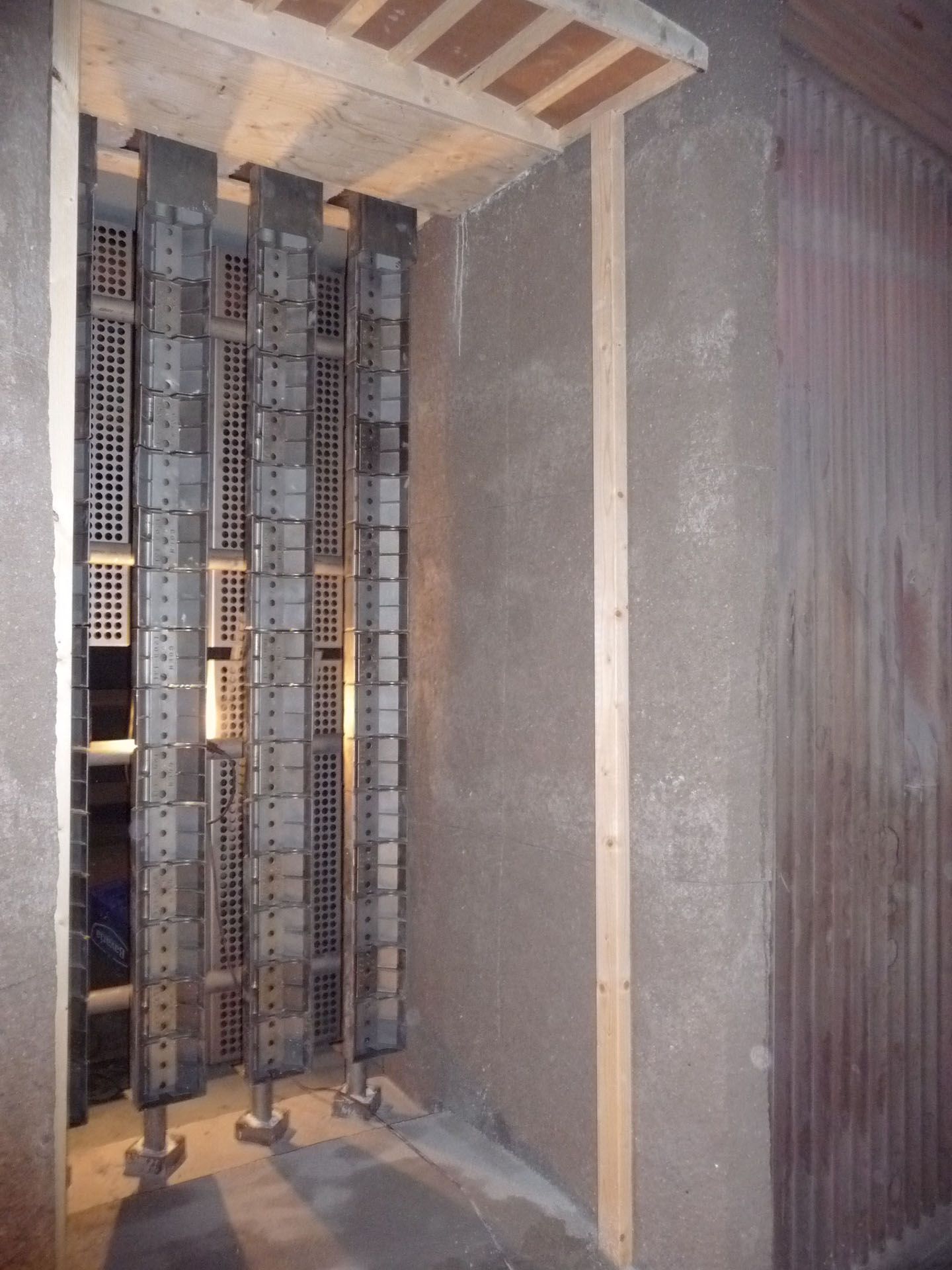

OVEN refractory lining

The design and installing of refractory and insulating materials in industrial furnaces, is since its foundation in 1983, the main activity of MOVI refractory installation. There are often extremely high temperatures in these kilns, high demands are made on the refractory insulating materials. The heat loss to the environment should be minimal and the oven outer shell should not be (too) warm. MOVI refractory has a very well-equipped warehouse. In these production halls, we can install the refractory lining in your furnace under ideal conditions. Working on location, in The Netherlands or abroad, is obviously no problem. Although MOVI refractory specializes in the lining of furnaces, both new and existing, we can be helpful in the design of the entire furnaces. The good international reputation MOVI refractory is based on a strong commitment to the product and a high degree of technical know-how. Each type of kiln has its own specific requirements for maximum efficiency. Whether we talk about heat treatment furnace for steel, galvanizing furnaces, kilns or incinerators, for this wide applications MOVI refractory always has the right materials available. The oven is a key element in many production processes and to let it run smoothly, only the best parts are good enough. MOVI refractory guarantees a reliable and safe product. Below are some of our projects in our workshop or on site.